The installation of a Timesavers 42-1350-WRb deburring, edge rounding and finishing machine by Ellesco at Dutton Engineering is delivering significant cycle time reductions, along with improved and consistent quality when it comes to deburring and graining punched, lasered, and waterjet cut parts.

Dutton Engineering based in Sandy, Bedfordshire is a specialist sheet metal sub-contractor. The focus of its 40 years has been stainless steel sheet. With customers in the food processing, medical and architectural sectors, among others, attention to detail, premium finish and quality products are essential to maintaining good customer satisfaction. With a turnover of £3 million and employing 40 people, the company prides itself on the quality of its work; most of which is visible in the finished product. “We pride ourselves on the quality and on-time delivery promises that we keep and, with our production focused mainly around high-value stainless steel. The parts we produce must reflect the materials inherent value in both visual and handling terms. For this reason, we place foremost focus on deburring and graining,” says Andrew Read, Managing Director, Dutton Engineering. The company aims to be more than just a ‘supplier of parts’. It encourages customers to visit its premises so that relationships can be built, and they can then draw on the expertise available at Dutton Engineering. Whether they just need sheet processing capacity or, a full design for manufacture solution.

Andrew Read and the new Timesavers 42-1350-WRb and Carter Environmental extraction unit installed by Ellesco at Dutton Engineering

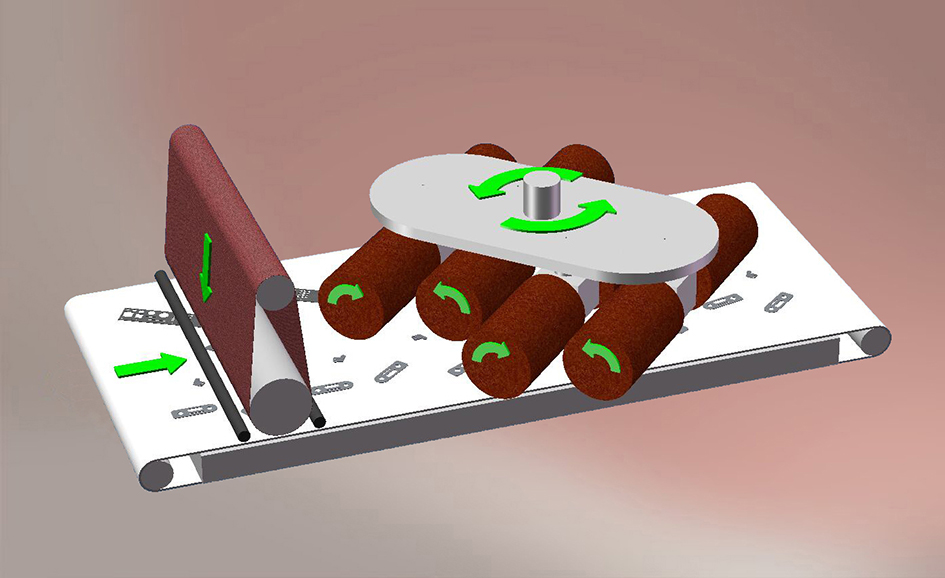

To support its customers Dutton Engineering has a comprehensive capacity list including punching, laser, waterjet, bending and forming, as well as milling and turning capabilities. The company uses two other Timesavers machines, which the company has had for several years. These are only used for surface graining / finishing operations. When a new contract demanded guaranteed consistent burr free parts (which contained multiple slots) the decision to purchase the Timesavers 42-1350-WRb was straightforward. With its combination of wide abrasive belt head and an eight brush rotary head, this 42 series machine combines both deburr and graining operations in a single pass. The inclusion of a vacuum table also adds greater versatility as the machine is capable of processing parts ranging from 1350 mm wide sheet up to 4500 mm long, down to parts measuring just 50 mm by 50 mm and up to 150 mm thick. “The advantage we are getting with the Timesavers machine is the ability to generate a consistent edge on components, which is something we now use as part of our sales proposition to customers. When compared with deburring manually not only have we gained in terms of quality, but also time, with processing times being reduced typically by 75 per cent for deburring parts. This is a major bonus as removing any burrs is important for us, especially with the work we do for customers in the food processing sector, where there is the need to eliminate any risk of personal injury or contamination.”

The ease of use of the Timesavers 42-1350-WRb is also a big plus for Andrew Read, as the size of the machine table means that multiple parts can be processes simultaneously, and only requires an operator to feed / remove parts, allowing Dutton Engineering’s highly skilled polishers, who used to be involved in manual deburring, free to do the work they are best suited to. “With just 30 minutes training we were up and running and once the machine is set, that’s it, there is nothing more to it. With the addition of the rotary brushes for deburring the new machine provides much greater flexibility in terms of production, with key benefits being the ability to process punched and lasered parts as well as those that have been cut using our waterjet machine, which may not have burrs, but do have sharp edges to them that need to be rounded off, whether on external or internal edges (such as holes and slots). Due to the importance of the finished product in visual terms we can also deburr sheet that still has its protective plastic coating applied.”

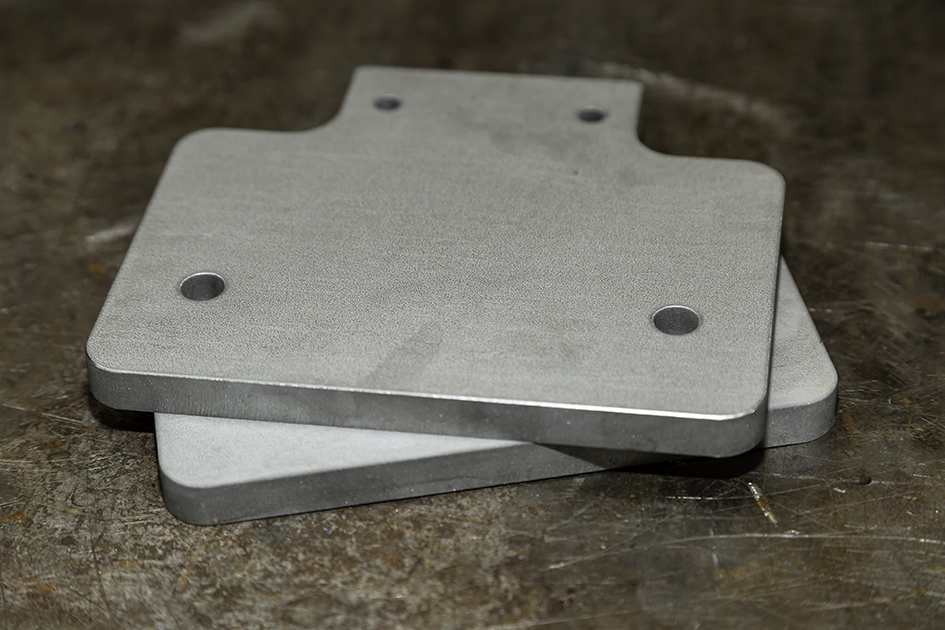

Waterjet cut parts have sharp edges removed and replaced by consistent edge finishing

In addition to deburring the Timesavers 42-1350-WRb machine also creates consistent edge radii, a process made simple by the easy-to-use control system allowing the machine to be set in minutes with minimal training. The Timesavers 42 series machines can be configured in multiple ways to suit specific customer applications with customers able to choose machines built with multiple abrasive belts or combinations of abrasive belt and rotary or stationary brushes. Machine widths can be 1000, 1350 or 1550 mm, with table speeds ranging from 0.2 to 10 m/min. The machine’s functions are controlled from the strategically positioned control panel which also includes a graphic interface to show details of the parameters that have been set. All of which makes the Timesavers 42 series ideal for removing burrs from parts that can be presented flat to the machine, whether they have been lasered or punched or to remove sharp edges from water jet cut parts. A wide range of materials can be processed, including stainless steel, mild steel, aluminium, and copper.

The brush and belt heads and general layout on the Timesavers 42-1350-WRb

“It is always particularly satisfying when a customer returns for additional machines and is further reassuring when the reasons that influence their decisions are the quality and performance of the product and the levels of service that we provide,” says Vincent Simonis, Managing Director, Ellesco. “We have worked with Timesavers for over 40 years, so we have been party to the invention of this technology. We know the designers, and we particularly know the capabilities of the machines inside out. This means we can quickly assess a customer’s requirements and ensure they have the right solution for their particular needs. Any decision on investing in new machinery that the customer