Frazer Nash Manufacturing Ltd is a company steeped in tradition with company founder Archibald Frazer-Nash designing and developing sportscars back in 1910. In 1929, the business evolved to engineering turret solutions for the Lancaster bombers and the Vickers Wellington. As a modern business, the Petersfield manufacturer is one of a select few manufacturers that can boast a complete service from 3 to 5-axis machining, turning, additive manufacturing and of course, EDM solutions supplied by FANUC.

In the modern era, the Hampshire Company still retains its roots in the aerospace sector whilst developing a specialisation for developing conveyor, packaging and air transportation systems and machinery for the heavily regulated food industry. Providing design, manufacturing and precision engineering services to exacting standards for a wide variety of industries and customers around the world, Frazer Nash has just invested in its fourth FANUC Wire EDM machine, a state-of-the-art FANUC ROBOCUT C600iB. Installed at the tail end of 2017, the new ROBOCUT C600iB perfectly complements existing FANUC ROBOCUT 0C and ROBOCUT 1C machines that have been efficiently and reliably running on the shop-floor since the early 1990’s.

Referring to why the company has opted to keep buying machine tools from FANUC, Mr Hayden Weeks, the EDM Supervisor at Fraser Nash Manufacturing says: “I’ve been involved now with FANUC for about 20 years and I’ve always rated their machines highly. They are very reliable machines and the technology down the years has greatly improved. Why change something if you’re really happy with it.”

Commenting on why the company invested in the newest ROBOCUT C600iB, that can support components up to 1050 by 820 by 300mm, Mr Weeks says: “We added the latest FANUC ROBOCUT C600iB, as we were looking for a machine with a bigger bed to accept larger parts. We also had a capacity requirement to fill and the cutting speed of the FANUC ROBOCUT C600iB certainly alleviates any capacity issues we had. Some of our other machines are getting a little old now, so the new addition really speeds things up. The new FANUC ROBOCUT C600iB is at least 20 to 30% faster than our existing machines. Even though the new machine operates at much higher cutting speeds, the cut quality and precision are much better than ever before. In fact, cut quality and precision are absolutely superb now”

“We are cutting all sorts of materials at all different thickness levels. A lot of our work is in the food industry, so we do a lot of plate work such as aluminium and titanium plates. On the new machine at the moment is a 3D printed maraging steel part and we’re cutting off the 3D printed base. From here, the job will go on to the next stage of production, which is 5-axis machining.”

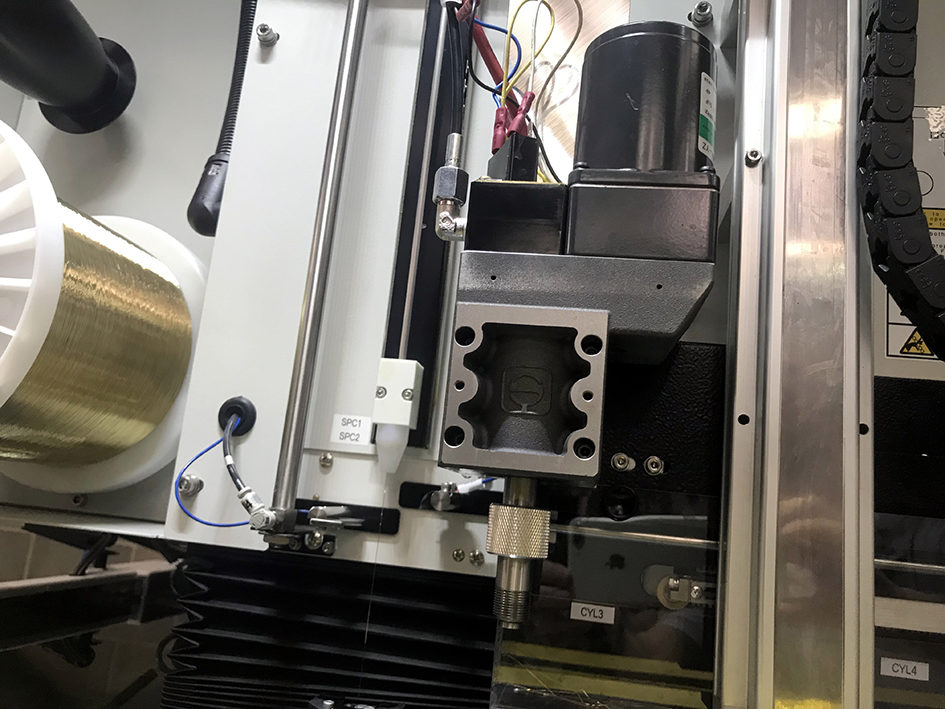

Machine Operator on FANUC EDM at Frazer Nash

The programming of the machines is all done off-line using the FANUC CAMi software. The CAMi system makes programming cylindrical, conical and 4-axis machining routines easy. You can mirror CAMi software directly to the CNC screen by using the remote desktop function. CAMi also offers multiple languages and a number of 2D or 3D data import options such as DXF, IGES and STEP files. “The software is really good. Once I picked it up, the FANUC software is easy to use, intuitive and it allows us to program and post across all our FANUC machines. It’s fantastic.”

The new B Series has a host of new features and one particular feature specified by the Hampshire Company was the EDM hole-drilling attachment. The bolt-on addition enables Frazer Nash to drill holes from 0.3mm to 3mm diameter through hardened steels and other challenging material types. As Mr Weeks continues: “The advantage of this system is that you don’t need to drill a plate before treatment or before its put on the wire machine. We load jobs straight on the machine and the drilling attachment will drill the hole. We can then centre-find the hole and feed the wire in for cutting operations. It means more unmanned hours without having to drill anything. This is all programmed from Macros in the machine, so we can do everything in one-hit. The drilling system is extremely easy to use and it is very easy to fit on the machine.”

Concluding on the purchase of the new FANUC ROBOCUT C600iB machine, Frazer Nash Manufacturing’s AM Development Manager, Mr Andy Brooker says: “The EDM machines are a perfect complement to the additive parts we manufacture, as they are the quickest way to cut bases and any other features away from additive manufactured parts. We’ve had FANUC EDM machines on site since 1990 and they have been absolutely brilliant from stage one. We can’t fault them. The FANUC machines are solid, reliable and perfect for what you want. The fact that we have a machine on the shop floor that has been working reliably since installation in 1990, really says it all.”