Complementing over 12,000 different iglidur types of plain bearings held in stock, the igus speedigus service is available for customised parts. In this week’s video, Gerhard Baus, plain bearing specialist at igus, provides an overview of the speedigus service, which is divided into four divisions: speedimould, speedicut, speedifit and speediprint.

The speedimould process covers the production of customised parts using injection moulding technology. The print2mould process produces a 3D-printed mould tool to make prototype parts or small batches of up to 500 pieces. A selection of 50 different iglidur tribological materials is available for this process, with all parts optimised for wear and friction. For batches of between 200 and 2,000 pieces, the alumould process produces aluminium mould tools, which are cheaper and faster to produce than traditional steel moulds, as no lengthy hardening is required. Depending on the complexity, the desired part is manufactured and delivered within three to a maximum of 21 days.

With speedicut, precise custom-made parts are machined from the iglidur bar stock. For simple components, this is the fastest and most economical method of producing individual parts in small and medium-sized batches. Machined parts also have tight tolerances. The speedicut process is straightforward; simply supply a 3D model or a 2D drawing with the specifications of the desired material and quantity to igus online via upload. Upon ordering, the speedicut parts are made and dispatched within 10 days.

The speedifit service is for component assemblies, whereby igus delivers them as ready-to-install modules. There is no minimum order quantity. Both standard and customised iglidur plain bearings can be assembled in a custom housing with matching shaft. Housings or assemblies can be made of any material. The most common materials for speedifit are aluminium, anodised aluminium, structural steel and stainless steel, as well as industrial plastics. The simplified procurement process increases productivity and reduces costs, and the short delivery and assembly times cut project and process costs.

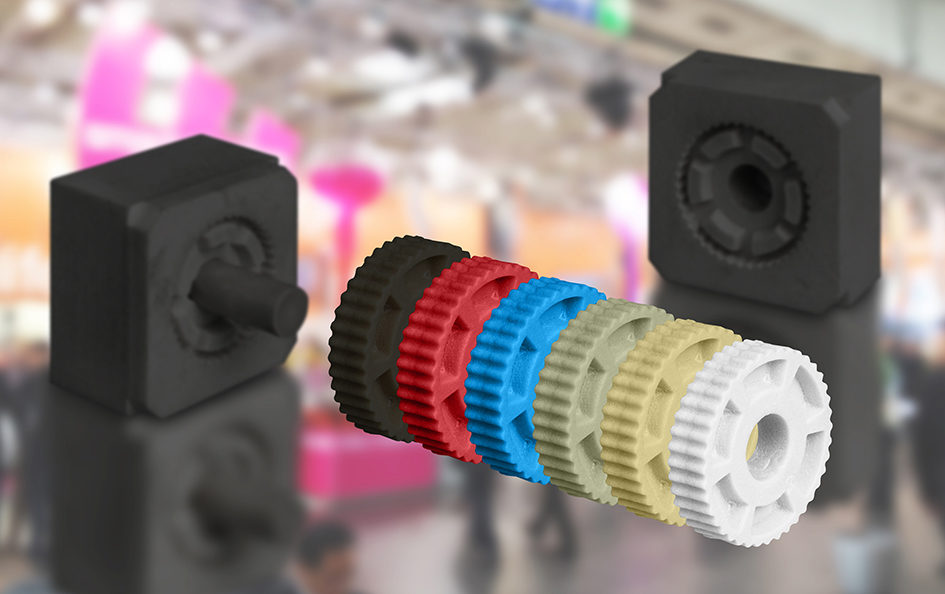

The final speedigus service is speediprint, whereby igus prints the part directly from a 3D file. The new iglidur i6 material for Selective Laser Sintering (SLS) is characterised by a wear resistance of at least six times higher than that of standard materials, offering a particularly long service life. Other engineering plastic materials are available for sterollithography (SLA) printing, all with high resistance to wear and friction. It is quick and easy to order 3D printed parts, simply visit www.igus.co.uk/3dprint, upload the design file and select the desired material. Upon ordering, the part will be dispatched within 1-3 days.

igus resources:

| LiveChat with our technical team at www.igus.co.uk |

| Follow us at twitter.com/igusUK |

| Watch our videos at igus.co.uk/YouTube |

| Connect to us at igus.co.uk/Facebook |

| Read our blog at blog.igus.co.uk |