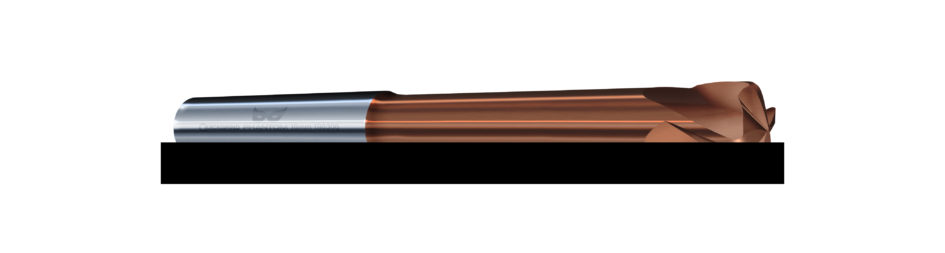

Quickgrind has launched its innovative Phantom series of solid-carbide end mills for enhancing a whole host of prismatic machining operations. These four-flute cutters have been designed to offer machine shops the opportunity to implement high-feed metal-cutting strategies that will boost metal removal rates and shorten cycle times. If required, a through-coolant version is also available – called Phantom Ice – to suit greater depth-of-cut requirements.

Stand-out features of Phantom end mills, which have the added advantage of being suitable for remanufacture, include a tough carbide substrate for strong, stable and efficient machining. The substrate, with its ability to withstand extreme cutting forces, is matched with an advanced coating and unique edge geometry to promote optimised chip flow and help maximise wear resistance.

Typical applications include rough-machining operations such as slotting, pocket milling and contour machining, as well as plunging and helical ramping. Machine shops will also enjoy gains when deploying Phantom end mills to perform pocketing with high length-over-diameter ratios. Thanks to their neck-relieved shanks, Phantom cutters are ideal for extended-reach applications in deep cavities, providing an excellent alternative to using standard small diameter, long and extra-long series mills that are prone to vibration, chatter and breakage.

Phantom high-feed performance end mills are perfect for use on workpiece materials that include stainless steel (including Duplex and Super Duplex), Inconel, titanium, tool steel, cast iron and hardened steels. In fact, Quickgrind says that machine shops are welcome to put the tools to the test when it comes to material. The company’s applications team loves a challenge and is more than happy to discuss specific applications.

The Quickgrind Phantom and Phantom Ice are available as 10, 12, 14, 16, 20 & 25mm diameter end mills. There are various overall lengths with bespoke versions delivered quickly to suit the client’s individual applications. By way of performance example, 12mm diameter Phantom end mills are capable of cutting at speeds up to 200m/min (0.7mm depth of cut) and feed per tooth up to 0.6 when machining materials with hardness values up to HRC30, such as carbon steels and cast iron. Even materials up to HRC50, like tool steels and titanium, can be processed at cutting speeds up to 180m/min and 0.4 feed per tooth.

In the words of one happy client “Using your Phantom is like running a 12 flute tool because the feed rates we run in Inconel are four times that of a 4 flute cutter.”

Using the Phantom Ice cutter with through-coolant capability, depth of cut can typically be increased to 0.9mm, depending on the application.

Email: sales@quickgrind.com

Web: www.quickgrind.com