DaRo Products’ success story started with a management buyout in 2000. Within the first year the company was turning over £600,000 fabricating sheet metal products for its customers. Since then the company has maintained a strong core of subcontract customers, manufacturing parts for many different products including commercial wood chippers.

However, in 2008 it had the opportunity to acquire the business of one of its customers, manufacturing UV water treatment systems, growing the DaRo UV Systems business to £1 million. It continued with this policy and has since acquired a second company designing, manufacturing and assembling Ministry of Justice approved lighting. Daro Products also supplies fibre optic enclosures, racks trays and patch panels to leading communications companies through Commscope. Damon Goodyear, Managing Director at DaRo Products says, “We built on our sheet metal and fabrication skills and we now have our own range of products which assures the future of our manufacturing facility. Furthermore, we have expanded the processes we carry out in house from CNC punching, forming and welding to include vacuum forming, powder coating and assembly.”

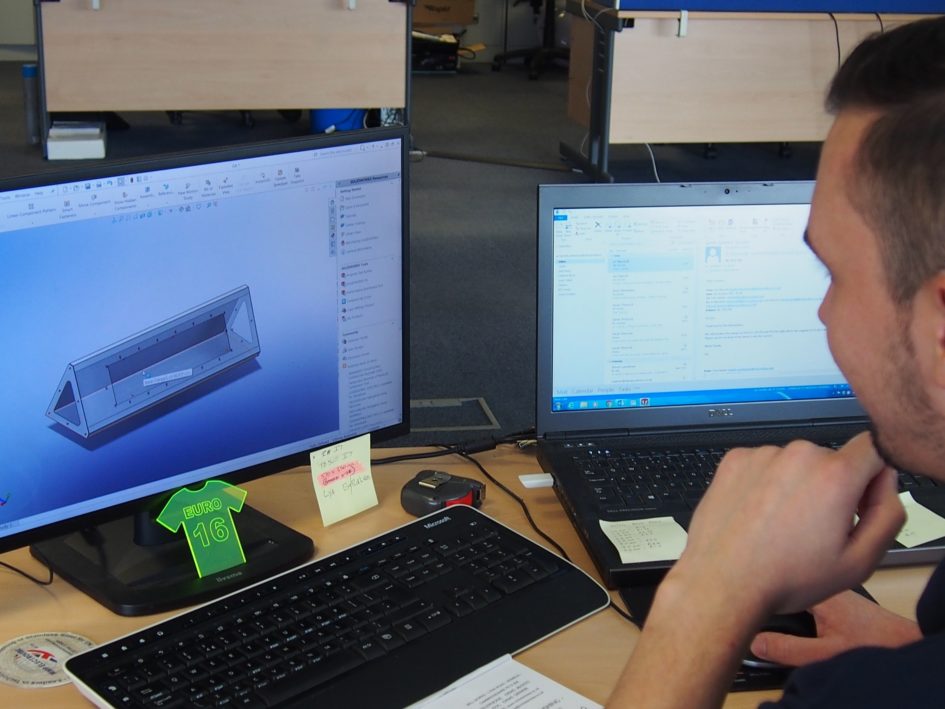

At the heart of its manufacturing facility are two CNC punch presses, a Rainer and a Trumpf TruPunch 3000. These are both programmed with Lantek Expert, which was first installed in 2005. Since the software was installed, the CNC punch presses have changed four times and each time, it has been easy to tailor Lantek Expert to programme the replacement machine. Damon Goodyear adds, “Before we installed Lantek Expert, we had a dedicated piece of software for our first Rainer machine. The flexibility to programme any machine with the Lantek Expert software was a very important in our purchasing decision.”

Many of the parts produced by DaRo have to be carefully de-burred to remove any sharp edges. To achieve this, the company uses a de-burring tool on the Trumpf machine which coins a small chamfer on the cut edge during the punching cycle. Damon Goodyear says, “We carry out this operation on all our parts, so that they can go straight to the customer or to assembly off the Trumpf without any secondary operation. We worked closely with Lantek to develop the process and incorporate it into the CNC programmes generated by Lantek Expert. The tool will accurately follow the profile of the job no matter how complex it is. Additionally, we can regenerate existing programmes with one click to incorporate de-burring into these as well.” Previously the company de-burred parts by hand so the on-machine method has saved a process, freeing up an operator to carry out other tasks. As well as de-burring, DaRo uses the punch machines to carry out forming operations such as knockouts. Currently, it subcontracts its laser cutting, but should the volume of work justify investment in its own laser, it will be able to use Lantek Expert to program this as well.

Most parts come as a DXF file, which goes straight in to the Lantek software. For reverse engineering and quality control the company also has a Virtek LaserQC which can scan parts in 2D and create a DXF file. This makes it possible to scan an existing part ready for CNC punching or compare a manufactured part with its drawing. Damon Goodyear says, “With Lantek Expert, we can produce a punching programme in a few minutes. Our subcontract business and the continuous development of our own products makes the automated programming in Lantek Expert important for keeping up with the pace of work.” Nests are organised to create a kit of parts as the company mainly manufactures complete products or assemblies. “Lantek is a very friendly and helpful company to work with and the software maintenance contract keeps us up to date with the latest technology. Previously it was very easy to get left behind. Now we can be sure that our manufacturing is operating at peak efficiency.”