Having produced its first lathe back in 1870, Halifax-based Broadbent Stanley has a long and distinguished history of designing and manufacturing large capacity machine tools. Its product portfolio over these years has evolved to add in grinding machines and the arrival of the Parkson range of mills. At one point it also offered a series of Vertical Turning Lathes (VTLs) and now history is repeating itself with the announcement of a strategic agency agreement with Radar Industrial, a Taiwan-based manufacturer of CNC VTLs.

The agreement will see Broadbent Stanley actively marketing and selling the Radar range in many markets, including the UK and Ireland, Egypt, Africa and the Middle East. “This is an exciting development for Broadbent Stanley and adds significantly to our existing portfolio of large capacity lathes, grinders and mills,” says Graham Thomas, Managing Director, Broadbent Stanley.

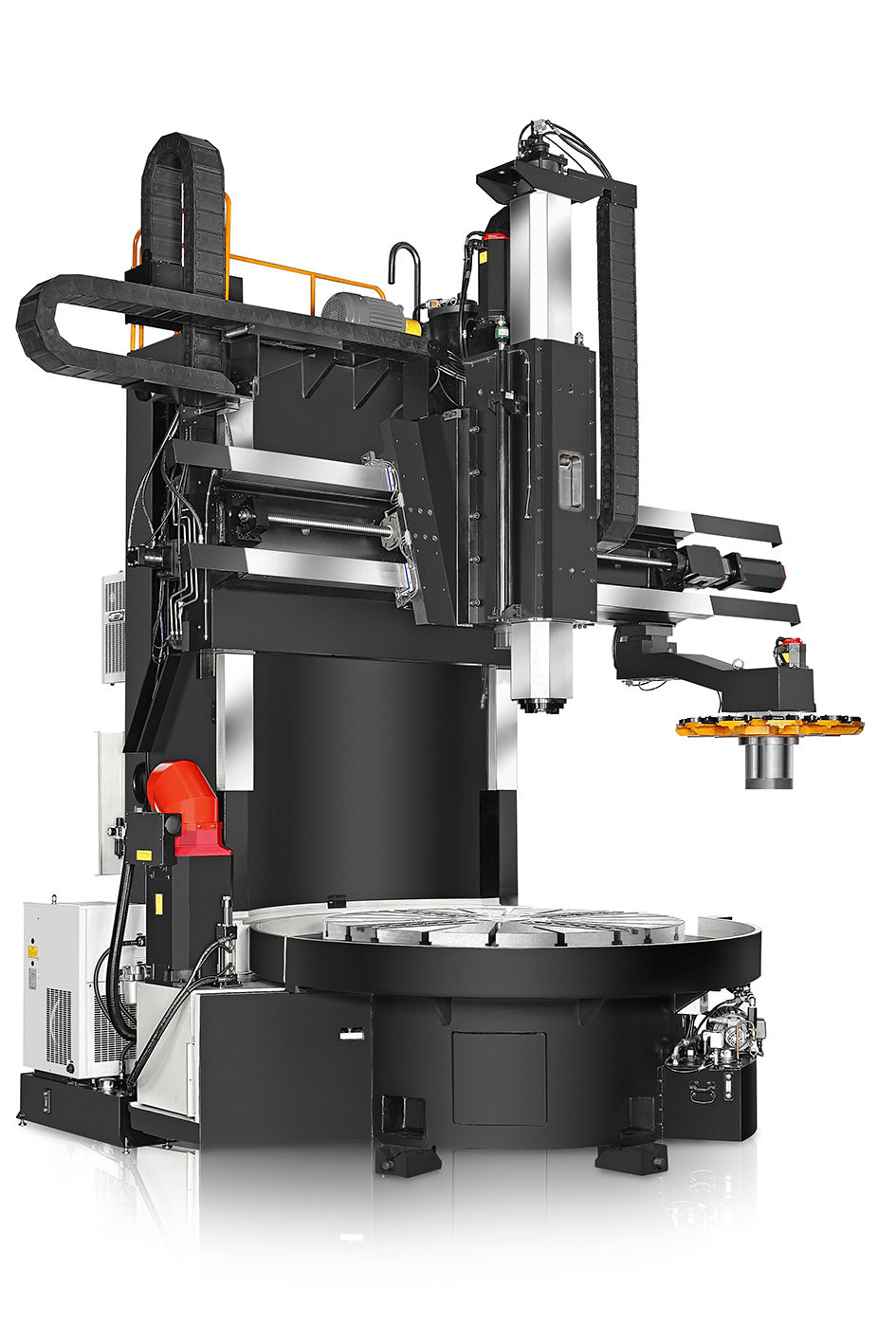

The Radar VTLs are available in three model designations, the RAL-12, RAL-16 and RAL-20 with maximum turning diameters ranging from 1500 mm through to 2400 mm and turning heights up to 1600 mm with a maximum workpiece weight of 13,000 kg on the largest machine. All three machines come as standard the Fanuc 0i-TF user friendly CNC system. As standard the machines are equipped with a 12-position toolchanger, which can be increased to 18 on the optional M-specification machines, with nine of those positions being capable of handling driven tooling, powered by a 15 kW (max) motor with up to 2400 revs/min available for the live tooling. For the larger of the three machines the main rotating table is powered by a 45 kW motor, with two speed ranges of 1 – 50 and 1 – 200 revs/min controlled via a high-torque (up to 23,750 Nm) gearbox.

As would be expected of machines of this size and capability construction is key and here Radar has employed new and advanced design concepts in the machine build. For example,

the main table features an innovative hydraulic static bearing design, where a floating hydraulic bearing is combined with a heavy-duty roller bearing, which sits in a rigid, one-piece, base casting. The result of this design leads to what is claimed to be the ideal combination of increased table load capacity and precision. Similarly, the RAL machines feature a patented octagonal ram design, which provides optimum damping and rigidity, when compared to more traditional square rams. Accuracy is also improved due to greater control of thermal expansion due to the design of the ram.

All of this is built around a multi-ribbed, one-piece, Meehanite cast iron column that features a wide span ribbed box structure combined with a 15-degree slant bed cross rail design, which reduces overhang. This combination equates to a strong and rigid machining platform that greatly reduces potential for vibration under heavy cuts, thermal expansion and, deformation caused by cutting stress. All leading to greater accuracy and quality of turned parts.

“We are genuinely excited by the opportunities presented by these machines from Radar, which fit neatly into our portfolio and will be backed by Broadbent Stanley’s extensive experience in sales and service of large capacity machine tools around the world.”