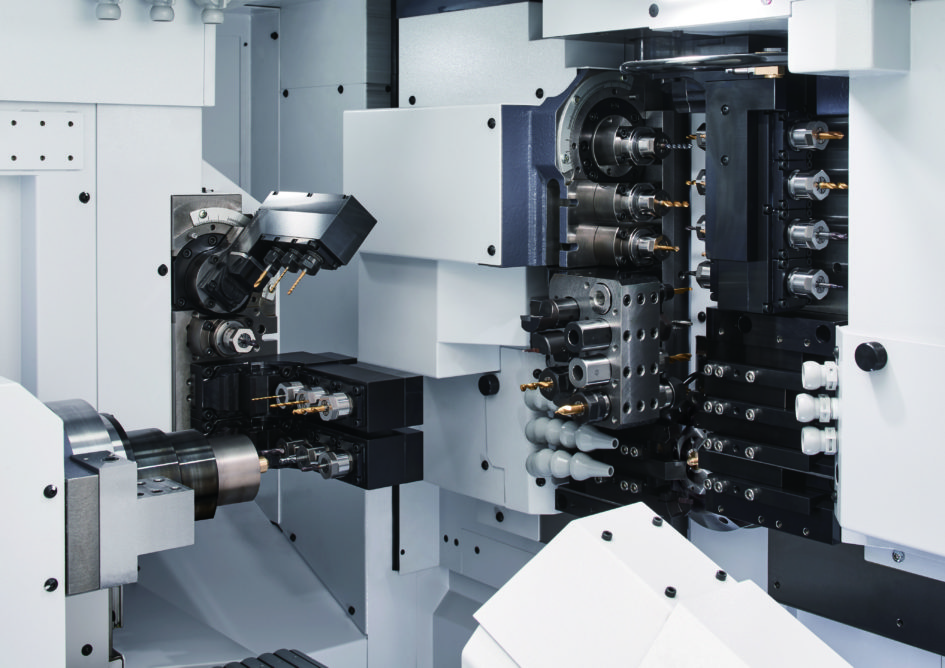

Introducing the Citizen D25 sliding headstock turn-mill centre with the next generation of Citizen’s advanced CNC system featuring touch screen and qwerty keyboard. Operational flexibility is increased for complex cycles with two gang vertical toolposts each with X-, Y- and Z- axes and one with a B-axis capable of both front and back machining. In addition there is a back toolpost and opposite toolpost. Now available from Citizen Machinery UK, the Cincom D25 has a tool capacity up to 59 tools with the added advantage of removable guide bush for more economic material use on shorter components.

The Cincom D25 is configured as a 10-axis machine which includes the 0 to 135 deg swivelling B-axis. This swivel axis is incorporated within the first (X1, Y1, Z1) axis gang toolpost capable of holding four double-sided driven spindles to service both the main and sub-spindles. In addition, the second gang toolpost (X2, Y2, Z2) is able to work independently or simultaneously with the (X1, Y1, Z1) toolpost to overlap for instance, rough or finish turning operations or apply in unison, drilling or milling based cycles.

Adding to the flexibility of the tooling application there is a further (Y3) back toolpost axis with one fixed or three driven tools having 90 deg adjustment for face, radial or angle machining. The opposite toolpost is positioned alongside the sub-spindle (X3, Z3) which provides a further two fixed tool positions

The power of the main spindle is 5.5 kW and 3.7 kW for the back spindle with both having a maximum speed of 10,000 revs/min. The gang driven tools are powered by drives of 2.2 kW with maximum speeds of 9,000 revs/min and the back driven tool speeds are 6,000 revs/min. Rapid traverse rates are 32 m/min with 24 m/min available on the Z2 gang toolpost.