The right cutter for the right job makes perfect sense and with WNT’s extended range of solid carbide milling getting that choice right has never been easier. Customers have an initial choice between WNT’s Mastertool series and Standard series cutters.

Cutters from the Mastertool series are Premium quality tools for high performance. They have been designed for specific applications and generate exceptional performance as a result. Customers that operate under challenging conditions that place high demands on production and quality should consider the Mastertool series as a starting point. For more conventional, less demanding, applications, where high quality cutting tools are still important, there is the WNT Standard series. WNT’s Standard series is the default for the majority of its customers faced with standard applications, but who still require guaranteed optimum performance.

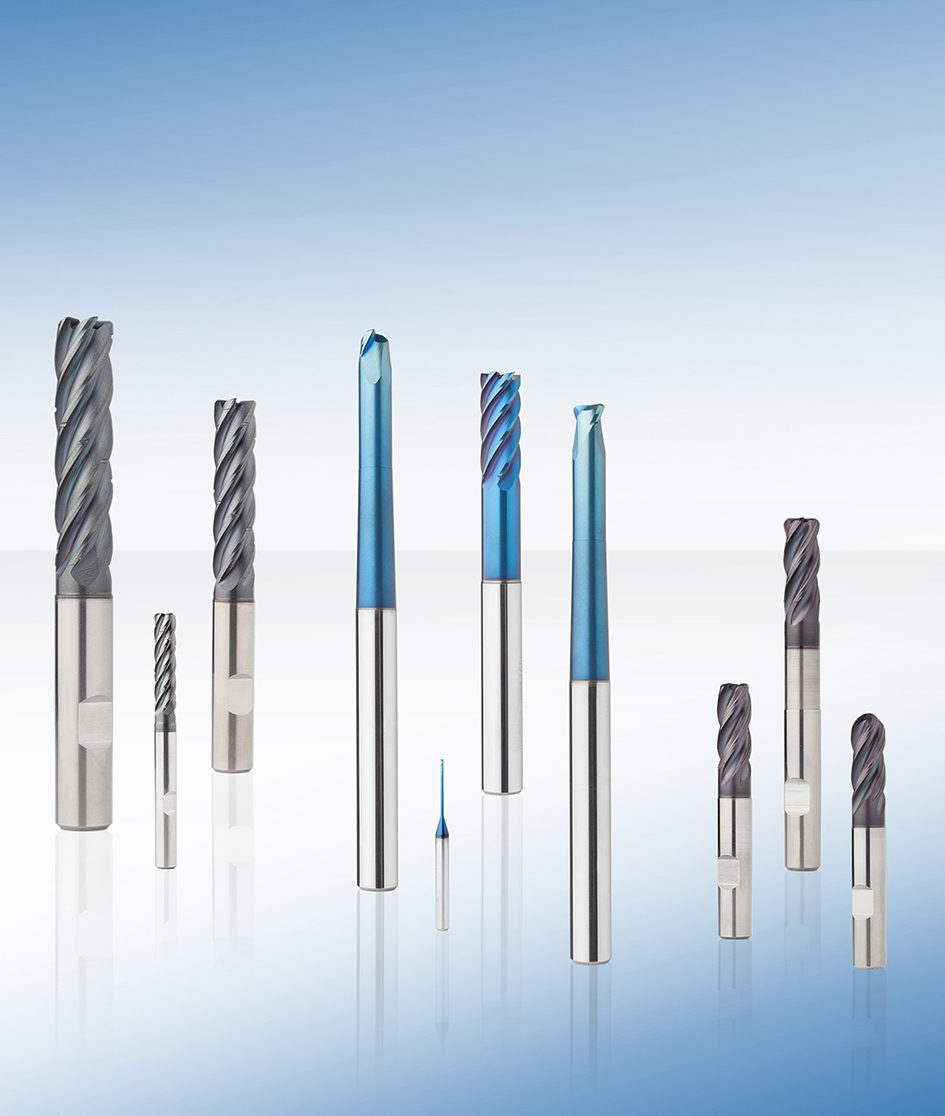

The WNT Mastertool series of solid carbide cutters includes the CircularLine and BlueLine ranges. CircularLine cutters deliver shorter machining times and longer tool life and are the ‘go-to’ choice for trochoidal milling were extended tool engagement

and consistent average chip thickness are key. The design of WNT’s CircularLine cutters ensures optimum and effective machining processes. The latest addition to the range, the CircularLine CCR-UNI is available for universal trochoidal milling as a 4xD end mill and a 3xD end mill with a shorter chip breaker, to provide maximum chip evacuation dependent on application.

The WNT BlueLine range has been developed for hard machining up to 65HRc and includes a mix of end mills, ball-nosed end mills and torus cutters with a variety of flute lengths. Also included in the Blueline range is a series of micro end mills and ball-nosed end mills from 0.2 mm to 3.0 mm diameter.

From the WNT Standard series are the renowned HPC cutters, these high quality end mills and ball-nosed end mills provide high levels of productivity and process security. WNT has recently extended the range to add even greater choice and flexibility when machining more standard parts and materials, with a wider choice of diameter/length combinations and cutters with specific corner radii available to machine steel and stainless steel as standard.