Some 1.5 million parts are despatched a year from Worthing-based precision subcontract machinist Roscomac that is achieving record on-time deliveries of 98 per cent that vary from completed assemblies and sub-assemblies to large machined castings and small turned parts. The complete operation of the 85 people company is driven by a philosophy of constant development of lean manufacturing techniques, supported by investment often exceeding £1 million a year and an ‘open-liaison’ people strategy which keeps the workforce up to date on the company and any issues arising.

Said Managing Director Joe Martello: “We invest in automation and the latest production technology which helps to overcome the shortage of skills we would require. However, it so important that we still need to grow our own engineers through constant support and by training, in order to maximise our return-on-investment and so improve how we support and what we deliver to customers.”

In the first six months of 2017, some £750,000 had already been allocated or spent which included the installation of the latest Miyano BNE-51MSY multi-axis turn-mill centre. Two further CNC sliding head turn-mill centre machines have also been ordered and soon to be delivered, again like the Miyano, each is from Citizen Machinery UK. The two machines, a Citizen L20-VIII LFV (LFV featuring low frequency vibration cutting technology) and a top-of-the-range M16-V will bring the total Citizen installations to 14 machines as two earlier Citizen machines are being sold.

The small part turning section featuring Miyano BNE-51MSY and Citizen CNC sliding head turn-mill centres.

Said Cell Leader Sean Keet: “The levels of operational flexibility in the Miyano BNE has enabled us to significantly reduce machining times and most important, improve overall productivity.” He explained how the new machine has replaced existing 3-axis machines and outlines how a family of 10 aluminium parts has seen four previous turning and a separate milling operation reduced to just one turn-milling cycle. A massive bonus is that average total cycle times per part has been cut from 13 mins to just 2.5 mins. A further complex stainless steel component which had three operations taking 11 minutes is now reduced to a single, four minute cycle.

He then outlined how additional advantages add to the firms return-on-investment policy by freeing-up setters to perform other tasks, also the reduction of lost time for each first-off inspection, lowering the risk of setting problems and part relocation errors influencing geometric relationships plus the control of work-in-progress made easier.

The flexibility of the BNE-51MSY is key to what Cell Supervisor Warren Harris, responsible for the machine, is achieving. It was specified with high pressure coolant, Kid 80 bar feed, a hybrid chuck and the latest Citizen UK developed Wizard programming aid. The machine is capable of single cycle cutting with three tools simultaneously overlapped at both ends of a workpiece at the same time created from up to 51 mm bar size.

The fixed-head 15 kW main spindle and two-axis 7.5 kW secondary spindle, both with maximum speeds of 5,000 revs/min, have the advantage of synchronised / superimposed control for both 12-station, all-driven turrets. Ideal for complex and heavier drilling and milling cycles, each driven tool position has 2.2 kW drive delivering 25 Nm of torque and speeds up to 6,000 revs/min.

Said Mr Harris: “The configuration of the 3-axis and 2-axis turrets gives us the flexibility to develop an application and room to add toolholders for instance, to overcome problems such as selective and controlled in-cycle deburring. This saves us additional manual or further operational process deburring tasks.”

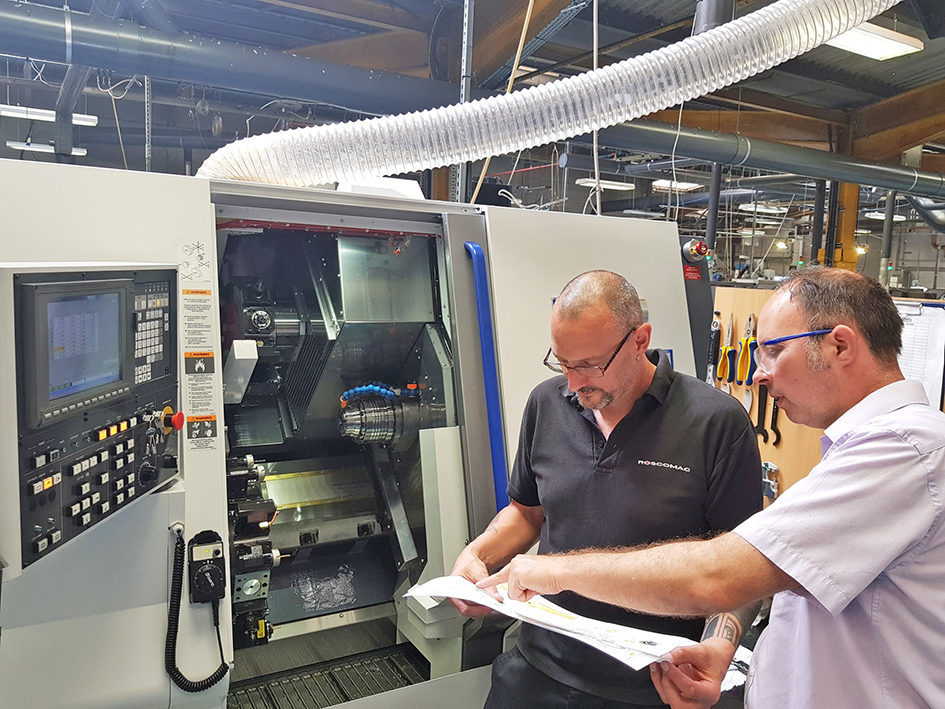

Miyano BNE-51MSY installation at Roscomac precision sub-contract machinist.

He describes how beneficial the training given by Citizen Machinery helped in developing different approaches to setting the operational cycles. “We had an initial induction at our works and two of us were sent for programming at Citizen’s headquarters in Watford. Then, after two months and adding to our own in-house experiences, further in-depth training was given.”

He maintains this helped to build a working relationship. He said: “Even now if we have a question or problem we text or email the application team and they quickly come back to discuss the issue and talk us through it.”

The family-owned business of Roscomac was set up in 1976 on an industrial estate of 21 units owned by Joe Martello’s father Fernando, who is still involved with the company. However, the company grew so fast that by 1999, subcontract production filled 20 of the 21 units.

The site was then sold and the current 43,000 ft2 factory on a two-acre site in Worthing set up and the philosophy of lean manufacturing and continuous investment in automation established. Indeed, with planning permission granted, in 2018 a 3,800 ft2 extension will be added and a complete new roof installed over the facility. As part of the drive to maintain quality (AS9100 Approved) and improve the working environment, climate control has recently been installed across the factory which is set to maintain a constant 22oC.

Today, some 50 CNC machine tools are installed including 13 Citizen CNC sliding head turn-mill centres and a large 104 pallet flexible manufacturing system. There are also 17 machining centres in the plant involved in supplying medical (20 per cent of £6.5 million turnover) aerospace (12 per cent) vacuum technology, oil and gas, motion and hydraulics and nuclear sectors involving the processing of a wide range of materials from plastics through to alloy steels such as Inconel. Parts are also exported to France, Germany and Czech Republic.

Mr Martello adopts the same working relationships with machine tool and equipment suppliers as most of his long term customers maintain with him and his team. This means his key equipment is only bought from a small group of ‘partnership’ suppliers for which Citizen Machinery UK (formally NC Engineering) has participated since 1990 and in that time installed 16 sliding head and two Miyano fixed head turn-mill centres plus the further two Citizen machines now on order.

Said Mr Martello: “As our relationship with customers is built on support, quality and on-time supply, suppliers such as Citizen are in the same category with the added capability to be consistent in providing us with leading technology developments that will keep us competitive and enable us to properly service our customer base. Our coming installation of the Citizen L20-VIIILFV is a classic case in providing a level of technology that will take us into another sphere of manufacturing that few competitors will be able to match for some time to come.”

Machining zone of Roscomac’s Miyano BNE-51MSY is capable of cutting with three tools simultaneously.

Current batch sizes range from 30 to thousands of parts plus a prototype and process development / design support service that is available to customers. Roscomac also maintain stock for key customers which also provides a major benefit to the subcontractor for tailoring batch work to economic quantity levels and helps to achieve its 98 per cent on-time delivery target. As a result, this has been improved over the last four years from levels of around 60 per cent. Indeed, with productivity targets now running at 200 per cent of man/hours available this has been aided by setting up five overlapping shifts during the five day week in order to maximise machine utilisation and spindle uptime.

In order to help maintain momentum of production with the workforce, every 3 months the workforce is taken aside to a conference room for presentations made by Mr Martello and key employees for a business update which encourages open communication. These sessions are backed up with live screens around the factory area showing current workloads and status of workflow, target and actual delivery dates achieved. Said Mr Martello: “This keeps everyone aware and involved. It also draws comment and constructive suggestions for improvement.”