The latest release of Alphacam, from Vero Software, continues to intuitively automate key CAD/CAM operations, improving manufacturing productivity and efficiency.

Automation Manager includes enhancements to simplify the workflow, including Multi-drill control, new Styles functionality, and further support for additional CAD file formats.

The introduction of Automation Manager Plus across all levels of Alphacam allows advanced automation to support the processing of Constrained Drawings and Parametric Sketches, and Part Grain Direction through sheet Grain Direction and Alignment Vector options. It also includes the Cabinet Door Manufacture (CDM) module.

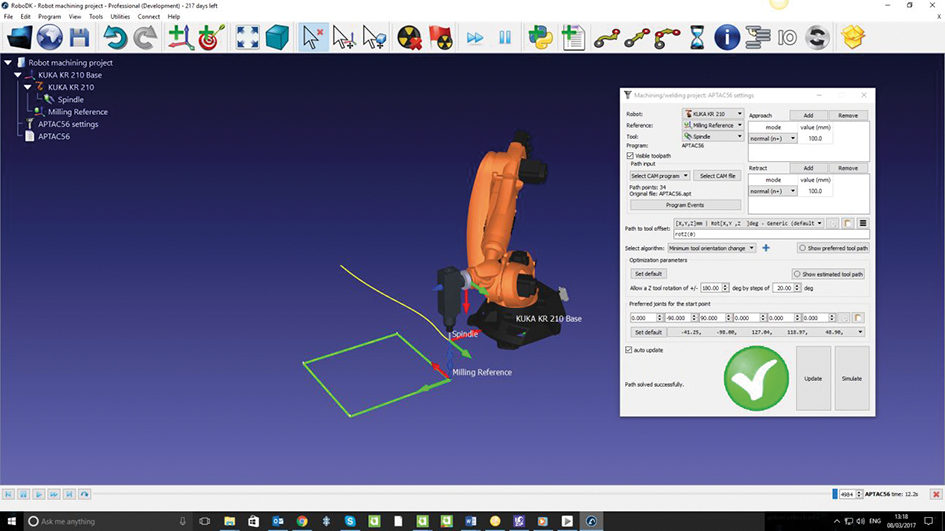

Alphacam 2017 R2 also sees the first release of its integration with robot simulation software, meaning that output toolpaths generated within Alphacam can be passed directly to RoboDK’s Offline Programming (OLP) to simulate robot kinematics, along with a range of applications and activities such as robot milling. RoboDK then outputs the OLP to the robot controller.

As part of the Vero Customer Experience Improvement Program, Alphacam integrates Microsoft Analytics to gather software usage statistics.

A new Reverse Cut Direction option has been added to Rough/Finish, creating toolpaths in the opposite direction to the tool direction on the geometry. Alphacam Brand Manager Simon Mathias says this is particularly useful when creating multiple passes around a shape which need to go in alternate directions, such as polishing and sanding profiled edges.

Sawing has been enhanced by controlling how the foul avoidance is applied. It can be applied to None or All of the selected machining geometries. Alternatively, a separate selection can be made for the avoidance geometries. Foul avoidance geometries appear in a new branch of the Operation tree, where geometries can be added or removed, and the selection remade.

In conclusion Simon Mathias says: “The automation enhancements in Alphacam 2017 R2 assist manufacturers to improve productivity and profitability by speeding up their manufacturing processes.”