Industrial Tooling Corporation (ITC) has now announced the launch of a new compact centring tool designed for small lathes and turning centres, the BIG KAISER CTL-90.

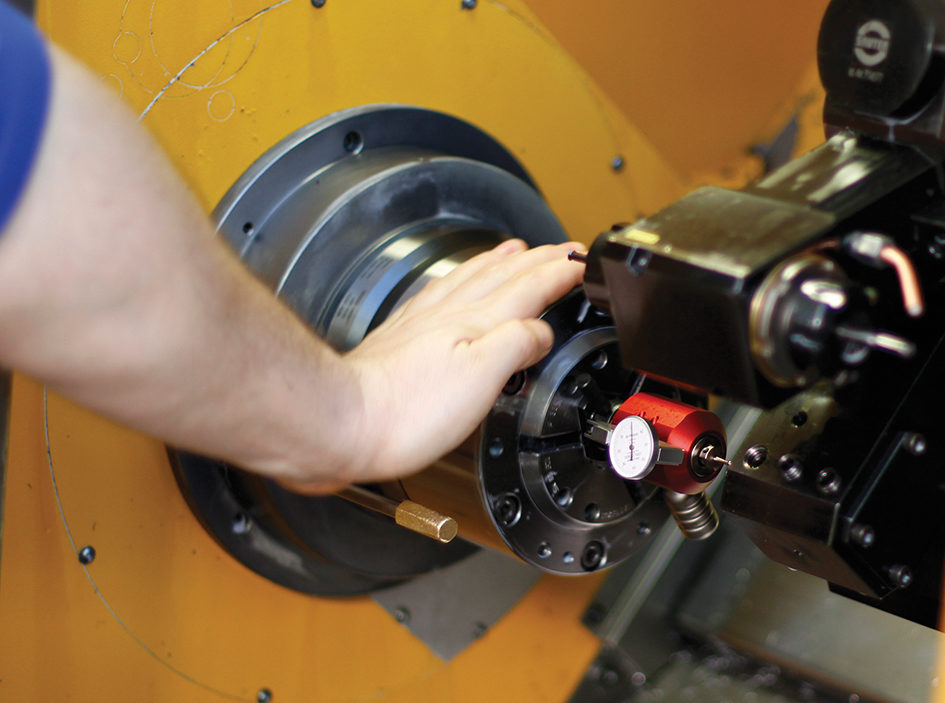

The new innovation from BIG KAISER has a stationary dial gauge that faces the machine operator at all times, rather than rotating with the spindle of the lathe. This significantly simplifies the tool and lathe chuck centring process, thereby saving valuable set-up time and improving operator productivity. In fact, machine setting can now be conducted from outside the machine when using the CTL-90. This makes the new setting device significantly safer than dial indicators that require the machine setter to lean into the work envelope.

The fine adjustment mechanism on the tool enables precise adjustment to within 10microns with a stroke of 2mm. Setting can be achieved with the spindle rotating at a speed up to a maximum of 100rpm. With a magnetic base to make the task of tool mounting incredibly simple, the CTL-90 expands the operator’s options with various mounting positions. The centring tool weighs 0.4 kg and consists of a dial indicator, magnet, adjustment bolt, stylus and a counter-balance weight.

“For busy operators who often oversee multiple machines at once, ease of use is truly essential,” says Peter Elmer, the CEO at BIG KAISER. “By ensuring that the dial gauge is always visible and legible, this new centring tool brings a new level of convenience and efficiency to the operator.”

Tel: 01827 304500

Email: sales@itc-ltd.co.uk

www.itc-ltd.co.uk