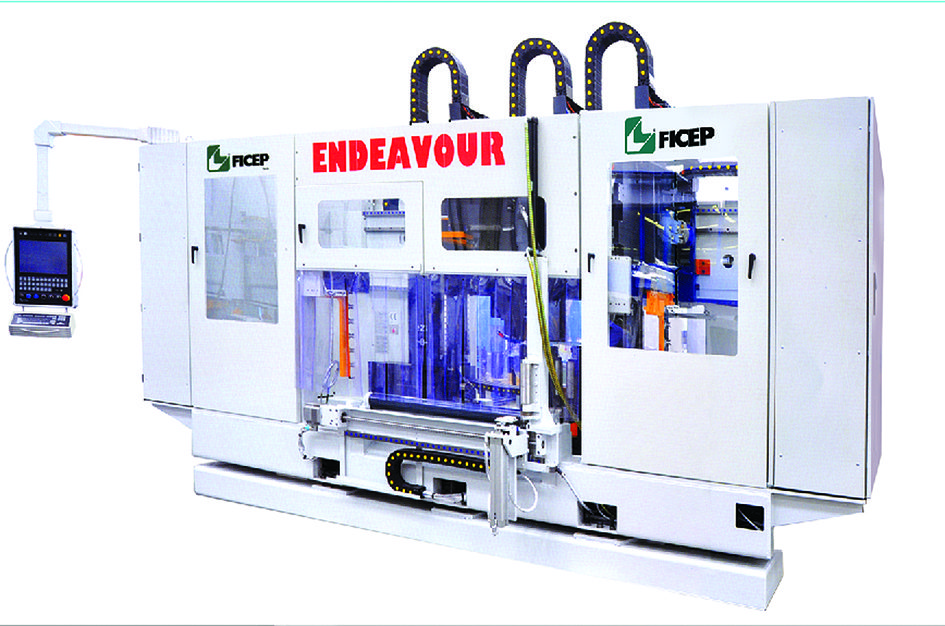

The Endeavour is one of the world’s most innovative CNC beam line which features 3 new direct drive, 31kw 5,000 rpm spindles with additional auxiliary axis movement, high speed positioning, 4 sides scribing and hard stamping marking unit.

Once a beam is clamped in position, drilling, milling and marking can be undertaken simultaneously on all 4 sides of the beam without any further actions by operator. Each drilling head moves rapidly and independently from one programmed position to another along the stationary beam for further drilling, milling or scribing.

Machining is therefore much faster resulting in remarkable increases in productivity and reductions in production costs.

Endeavour can be used as a stand-alone machine in combination with a high speed Katana CNC saw or a coping unit with plasma or oxy robotic thermal cutting heads. When combined with the Katana, a patented magnetic unloader allows the drilling and sawing of short piece without operator intervention.

Andrew Hirst, Managing Director of the UK’s largest independent steel stockholder, Barrett Steel Services,, commented –

“We already had FICEP saw drill lines but we wanted to further increase our processing volumes and to meet our customers requirements. The Endeavour was exactly what was wanted and fits perfectly into our existing production lines, helping us to further enhance our customer services and delivery times.”