As aerospace original equipment manufacturers and supply chain companies face increasing pressure to produce more fuel-efficient aircraft – wire EDM (WEDM) is emerging as a key machining technology.

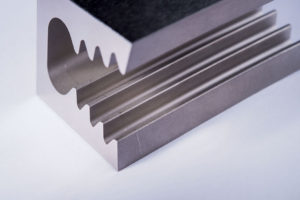

Due in large part to a body of evidence generated by David Welling at the Laboratory for Machine Tools and Production Engineering (WZL) at RWTH Aachen University (Germany), WEDM has the potential to replace broaching as the technology of choice for the manufacture of fir tree slots for found in high-pressure compressor and turbine disks. (Fir tree slots are the spaces in turbine disks into which blades’ fir tree roots fit).

Welling, Team Leader of the Research Group Electro Discharge Machining at the Chair of

Manufacturing Technology at WZL, is driving much of that research. Welling’s interest in aerospace machining technologies was triggered by an advanced internship at one of the industry’s

main original equipment manufacturers (OEMs).

Following that internship, he finished his study of mechanical engineering for his diploma degree, and in 2010 authored the first of three break-through studies on WEDM in the manufacture of jet engine components. Welling was part of the EU-funded ADMAP-GAS project to investigate alternatives to broaching for fir tree structures in gas turbine blades and disks.

“Jet engines must become more fuel efficient, and that means developing advanced high

temperature materials that are often hard to machine,” he explained. “The topic of fir tree slot production using WEDM was initiated during discussions with the Research Group at WZL and GF Machining Solutions.”

Finding solutions to industry problems

As part of his doctoral thesis, Welling was required to take an industry problem, break it down to its fundamentals, and provide solutions. With the soaring demand for new aircraft by the year 2030, and with every passenger jet requiring more than 500 fir tree slots, it was obvious to Welling that a more efficient and secure fir tree slot manufacturing method was needed.

“I wanted to investigate whether a more efficient method could be found that could replace broaching” he said. “Broaching tools have obvious limitations – one of these is the high tool wear that results from the increased toughness of aerospace materials. Also, Broaching machines require a lot of floor space, have a high initial investment cost, and offer low flexibility.

“For example, it takes a relatively long time to change a broaching tool, and you need a special tool for every fir tree slot. And that tool—which is very expensive to replace—could take more than six months before it’s manufactured and is available to use.”

WEDM has long been considered a mature technology with little innovation potential and, until about 10 years ago, was not considered a viable process for full fir tree slot production due to the recast white layer left on components by earlier WEDM generator technology. But Welling’s research has shown that WEDM now, with the advent of sophisticated digital generator technology, compares well to broaching in terms of surface integrity and part tolerances – both important in fir tree slots.

Exploring the WEDM advantage

So far, Welling’s research has shown through component high cycle fatigue studies that WEDM compares to broaching in terms of component fatigue life, and that WEDM is actually capable of machining fir tree slots with the required accuracy.

In addition, Welling said, WEDM offers an advantage when it comes to automation since it offers the process monitoring capabilities necessary to ensure machining (part) quality.

“Broaching, on the other hand, is perceived as a difficult process to automate,” said Welling.

“WEDM is a fully controlled process. You can monitor the control data, trace it back, and make the correlation to the surface to get a quick, in-process quality assessment,” he explained.

“Furthermore, WEDM does not present the tool wear challenges inherent in broaching. In WEDM, since the tool is the wire that is being unwound from the spool, there’s a new tool being used for every process second.”

Welling’s research has also shown that, while broaching uses brute force to produce forms, WEDM is a virtual ‘force-free’ process capable of cutting the very fine geometric radii of fir tree slots.