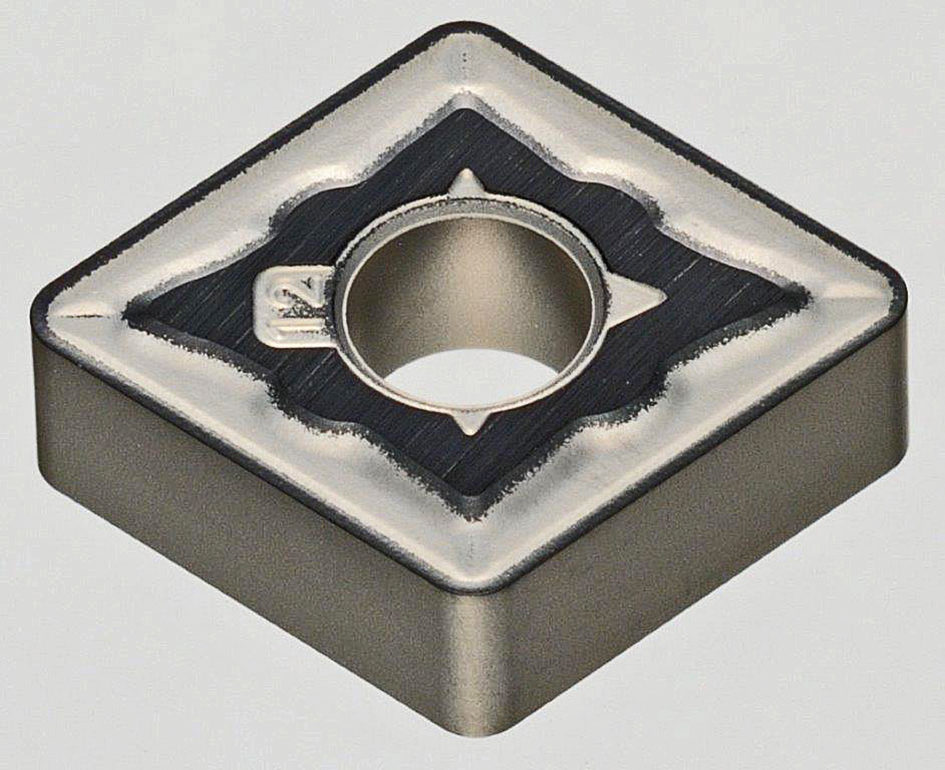

Sumitomo Electric Hardmetal has extended the use of its highly successful Absotech Platinum Technology with the launch of AC6020M insert specifically for turning stainless steel at higher speeds up to 250m/min and where continuous or very light duty interrupted cuts are being used.

The AC6020M insert extends the range of successful stainless steel insert grades AC6030M and AC6040M following their pioneering launch in 2015 with the former targeted at general machining and the latter, for heavy and interrupted turning applications.

The new grade introduces substantial resistance to fracture and notch wear and here the stress controlled Absotech Platinum Technology provides extended resistance to chipping that is up to double that achieved by more conventional coated inserts. Meanwhile, due to the ultra-smooth surface smoothness and its adhesion properties, this means the likelihood of abnormal damage is significantly reduced.

Absotech Platinum Technology is a recently developed chemical vapour deposition (CVD) boride-based titanium compound that provides the outer protective layer on the five-stage multi-layer structure of the insert and creates an ideal balance between wear resistance and toughness with the substrate material.

Cutting speeds up to 250m/min can be used on ferritic, martensitic and austenitic stainless materials which can be prone to zone hardening under cut and can often lead to the edge of the insert becoming chipped. As thermal conductivity is low, higher temperatures are created at the cutting edge with the added risk of plastic deformation.

As well as the onset of built-up edge which under cutting conditions, alters the geometry of the insert and leads to premature tool failure.

Sumitomo has also incorporated its latest NEF chipbreaker for use with depths-of-cut between 0.1 mm and 0.2 mm. The chipbreaker reduces the diameter of the chip curl thus adding the advantage of improved chip control even at low cutting depths.

Tel: 01844 342081

www.sumitomotool.com