The high speed turning of aluminium alloys and non-ferrous materials has now been taken to a new level with the introduction of the NTK PD2 insert line. With exceptional edge sharpness and adhesion resistance, the new PD2 range of inserts are ideal for extending tool life and productivity on difficult to machine alloys.

The new PD2 grade has a PCD grain size smaller than 1micron, which gives the new grade unrivalled edge toughness with impressive wear resistance characteristics. This super-micro grain PCD enables the end user to conduct machining at cutting speeds beyond 220m/min with depths of cut from 0.1 to 0.25mm on nylon, plastic, copper, brass, epoxy and other non-ferrous materials with performance on aerospace grade aluminium alloys being particularly impressive. Furthermore, the edge toughness and composition give the PD2 tool life and consistency that is unrivalled when conducting interrupted and continuous machining.

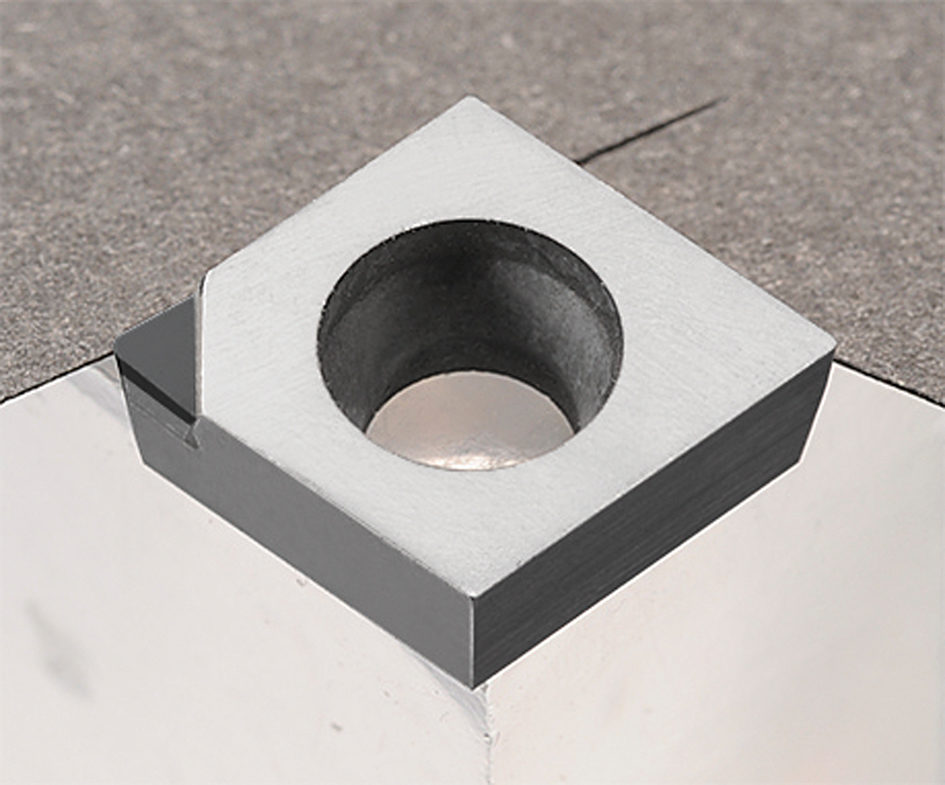

The new PD2 is available as a positive insert with a CCMT, DCMT and TPMT geometry that provides a PCD cutting edge length of 2.3mm with the option of a 0.2 or 0.4mm corner radius. The various insert geometries and available with an insert thickness from 2.4 to 9.5mm. Complementing the positive geometry inserts is a complete selection of negative type inserts for the PD2. The CNMX, DNMX and TNMX geometries have a cutting length of 3.4, 4.5 and 3mm respectively and all inserts have a 4.76mm thickness that promotes strength and rigidity. The three insert types are available with a corner radius of 0.4 or 0.8mm to prevent edge breakages and prolong tool life and consistency.

Both the positive and negative type single cutting edge inserts are available with a range of toolholder designations to suit all types of turning centre from the smaller sliding head centres through to heavy duty turning machines.

Tel: 01442 281072

Email: ntkcuttingtools@ngk.co.uk

www.ntkcuttingtools.co.uk